Product features

Low insertion loss

Fast switching speed

LCD display screen, intuitive display light path status

Panel key and network interface command mode for light path switching setting, and can be operated by the chain interface command lock key

Output port (OUT port) with light power monitoring

Scope of application

Multichannel optical monitoring in optical transmission systems

Automatic LAN multi-light source/detector switching

Optical sensing multi-point dynamic monitoring system

Optical testing system for optical fiber, optical devices, network and field engineering optical cable testing

Optical device assembly and adjustment

Technical parameters

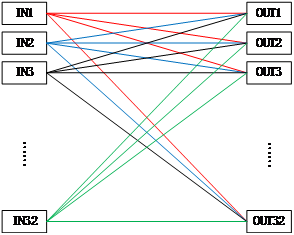

Type no. | MFSW-32X32-2U-LP |

Working wavelength | 1260 ~ 1650nm |

Test the wavelength | 1310/1550 nm |

Insertion loss | ≤4.5 dB |

Monitor optical power range | +20 ~ -50 dBm |

Monitor optical power accuracy | ±0.5 dB (+20 ~ -30 dBm) ±1.0 dB (-30 ~ -50 dBm) |

Monitor optical power resolution | ±0.01 dB |

repetitive | ≤±0.2 dB |

Return loss | ≥45 dB |

crosstalk | ≥50 dB |

Wavelength dependent loss | ≤0.8 dB |

Polarization dependent loss | ≤0.3 dB |

Switch time | ≤ 50 ms |

Optical fiber type | SM(9/125um) |

Connector type | LC/PC |

Monitor the port | RJ45、RS-232 |

Working power supply | AC: 85 ~ 264 V(50/60Hz)或 DC: 36 ~ 72 V |

Working temperature | -10 ~ + 55℃ |

Storage temperature | -40 ~ + 80°C |

The case type | 19-inch standard 2U rack(483×500×89mm) |

Equipment maintenance

Reasonable use and proper storage of equipment can maintain good performance index for a long time and extend its service life, so proper maintenance is required:

(1)、The equipment should avoid strong mechanical vibration, collision, falling and other mechanical damage.Transport must have good packaging and vibration, rain and waterproof measures;

(2)、The equipment should be kept clean and the working environment should be free of corrosive gases such as acid and alkali.Use a clean towel with water or soapy water to gently scrub the chassis and panels.Do not use alcohol and other solvents to scrub.

(3)、Remove the fiber cable should be timely covered with dust caps to prevent hard objects, dust or other dirt touching the end face of the fiber.

Please feel free to contact us for any unspecified matters.We would be glad to hear your valuable comments.

Equipment maintenance common fault handling

The fault performance | Possible reasons for | The solution |

No display after boot | The electricity is not properly connected | Reconnect the power and turn it on |

Excessive insertion loss | The end face of the connection head is soiled | Rinse the end face of the smooth connection head and fix the connection head.Check the end face for damage. |

The panel cannot switch light paths | The panel keys are locked | Allow panel keys to be used by sending commands through the serial port. |

The upper computer instruction is invalid | The serial port is not set correctly | The query checks the serial port Settings |

The serial line is not properly connected | Power off first, recheck the serial line, and then power on. |

If you need any support, Please contact us.